Table of Contents

In the chilly Canadian climate, the quest for efficient and reliable heating solutions is of paramount importance. One such solution that stands the test of time is the oil furnace. In this article, we will delve into the intricacies of what an oil furnace is and unravel the fascinating process of how these systems work, shedding light on their components, efficiency, environmental impact, and more.

What Is an Oil Furnace?

An oil furnace is a type of heating system that relies on heating oil as its primary fuel source. It stands out in the realm of furnaces due to its robust and dependable heating capabilities, making it an ideal choice for colder climates like Canada. Unlike electric or gas furnaces, which use electricity or natural gas for heating, oil furnaces burn heating oil to generate the warmth needed to keep indoor spaces comfortable.

One significant advantage of oil furnaces in Canada is their energy density. Heating oil packs a powerful punch in terms of heat output, ensuring that even in extreme cold conditions, an oil furnace can efficiently and effectively warm up homes and businesses. This energy density also contributes to the longevity of the system, as less fuel is needed to produce the desired level of heat. This makes oil furnaces particularly well-suited for areas with harsh winters, where a consistent and powerful heat source is paramount for comfort.

In contrast to electric furnaces, which can experience fluctuations in performance during peak electricity demand, oil furnaces operate independently of the electrical grid. This autonomy ensures that even in power outages, residents can rely on their oil furnaces to provide continuous heating. Additionally, oil furnaces tend to have a longer lifespan than electric furnaces, offering a durable and reliable heating solution for the long term.

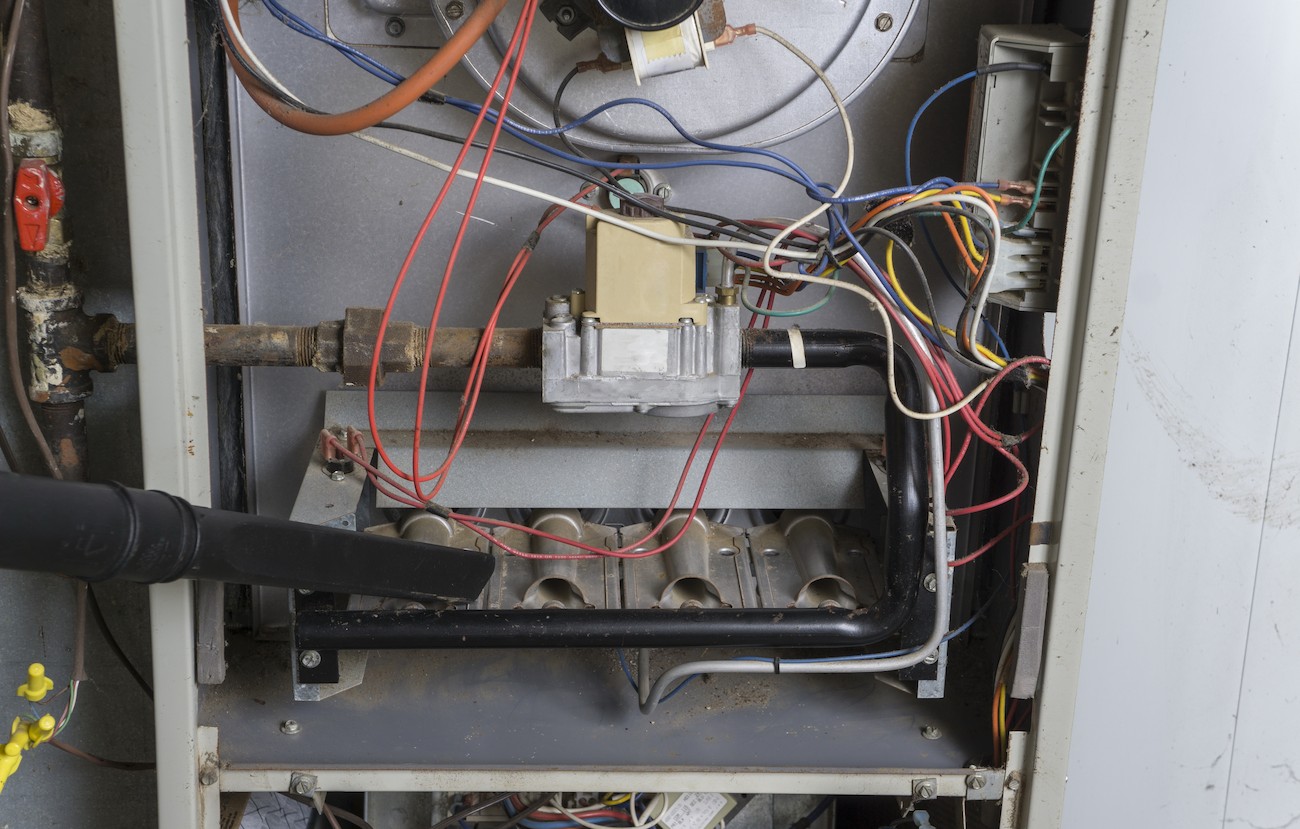

Components of an Oil Furnace

To grasp the inner workings of an oil furnace, let’s explore its key components, each vital for efficient heating.

1. Burner: The burner is the ignition point, sparking the heating oil to start the combustion process. Modern versions feature advanced controls for optimized fuel combustion.

2. Combustion Chamber: This chamber hosts the combustion process, where heating oil transforms into heat, creating the high temperatures required for effective heating.

3. Heat Exchanger: Efficiently transferring heat generated in the combustion chamber, the heat exchanger ensures optimal extraction of thermal energy for distribution.

4. Blower: Taking over after heat extraction, the blower circulates the warmed air through ductwork, evenly distributing warmth. Modern versions offer variable-speed settings for energy-efficient heat distribution.

5. Thermostat: Functioning as the conductor, the thermostat allows users to regulate indoor temperature. Advanced thermostats come with programmable settings for personalized temperature control, enhancing energy efficiency.

Regular maintenance of these components ensures the oil furnace operates at peak performance, providing reliable and consistent heating.

How Does Oil Furnace Work?

Delving into the intricacies of an oil furnace’s operation unveils a fascinating process that transforms heating oil into the warmth that blankets homes and businesses during cold Canadian winters. The journey begins with the careful orchestration of several key components.

Burner Ignition

The heating process commences with the burner, where a controlled ignition sparks the heating oil. This combustion sets the stage for the release of thermal energy, the cornerstone of the entire heating operation.

Combustion Chamber

Within the combustion chamber, the burning heating oil generates intense heat. This chamber is engineered to sustain high temperatures, fostering efficient combustion. The result is a torrent of thermal energy poised for extraction.

Heat Exchanger Efficiency

The heat exchanger steps forward to harness the thermal energy produced in the combustion chamber. This component efficiently transfers the heat to the circulating air, ensuring maximum extraction before the air embarks on its journey through the ductwork.

Blower Distribution

With the extracted heat in tow, the blower takes the lead, propelling the warmed air through the ductwork. Variable-speed blowers, common in modern oil furnaces, allow for customizable airflow, optimizing the distribution of heat to different areas within the building.

Thermostatic Regulation

The thermostat orchestrates this entire process, acting as the maestro of temperature regulation. Users can fine-tune the indoor climate, with advanced thermostats offering programmable settings that adapt to daily routines, ensuring energy efficiency without compromising comfort.

Continuous Regulation

The thermostat not only initiates the heating process but also continuously monitors the indoor temperature. As the set temperature is reached, the thermostat instructs the furnace to pause, conserving energy until additional heating is required.

Efficient Cycling

Oil furnaces operate in cycles, responding dynamically to the heating demands of the space. This efficiency ensures not only consistent warmth but also optimal energy utilization, aligning with the push for sustainability.

Any misstep among the furnace components can lead to disruptions, uneven heating, or even safety concerns. Swift attention to these issues is paramount, and with HVAC Service Solutions, our immediate furnace repair service ensures the seamless restoration of your heating system, guaranteeing your comfort and safety throughout the coldest seasons.

Efficiency and Advantages of Oil Furnaces

Modern oil furnaces have evolved to offer impressive efficiency, providing reliable heating in the face of the coldest climates. Their high energy density ensures a potent heat source, requiring less fuel for optimal performance. This not only contributes to consistent warmth but also enhances the longevity of the system. The durability of oil furnaces, coupled with their ability to operate independently of the electrical grid, positions them as robust and dependable heating solutions.

Cost and Installation Considerations

When considering an oil furnace, it’s essential to weigh the upfront costs against the long-term benefits. While initial investment may vary, the efficiency and durability of oil furnaces make them a cost-effective choice for sustained comfort. Installation costs should also be factored in, ensuring a seamless integration into your heating system. Additionally, it’s worth exploring potential long-term savings and any available incentives that may further enhance the economic appeal of opting for an oil furnace. This approach allows you to make informed decisions based on your heating needs and budget considerations.

Find out how you can save up to $10,000 on your new furnace with government rebate programs in Canada in our previous article.

https://thehvacservice.ca/how-to-save-money-with-government-furnace-rebates-in-ontario/

How to Maintain an Oil Furnace

Preventing issues with your oil furnace is often easier than dealing with repairs. Regular maintenance is key to ensuring the efficient and trouble-free operation of your oil furnace. Here’s a guide on how to maintain your oil furnace to keep it running smoothly.

1. Regular Inspection: Conduct routine inspections to check for signs of wear, corrosion, or leaks. Address any issues promptly to prevent further damage.

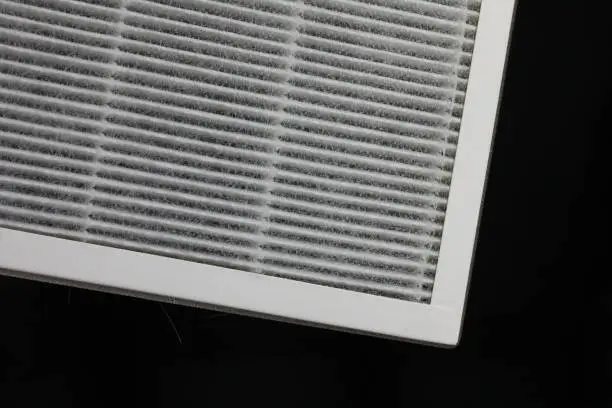

2. Filter Replacement: Change the oil filter regularly to maintain optimal fuel efficiency. A clogged filter can lead to reduced performance and increased energy consumption.

3. Clean the Heat Exchanger: Periodically clean the heat exchanger to remove soot and debris. This ensures efficient heat transfer and prevents potential malfunctions.

4. Check and Adjust Burner Settings: Inspect the burner assembly for proper ignition, and adjust settings if necessary. Proper combustion is essential for fuel efficiency and a clean burn.

5. Lubricate Moving Parts: Keep all moving parts well-lubricated to reduce friction and wear. This includes the blower motor, fan, and other components with moving elements.

6. Inspect and Clean the Flue Pipe: Check the flue pipe for any obstructions, such as soot or debris. Clean the flue to maintain proper ventilation and prevent the risk of carbon monoxide buildup.

7. Monitor Fuel Tank Levels: Regularly check the fuel tank levels to ensure an uninterrupted fuel supply. Consider scheduling automatic deliveries to prevent running out of fuel during colder months.

8. Annual Professional Inspection: Schedule an annual inspection by a qualified technician. A professional can identify potential issues early on and perform any necessary adjustments or repairs.

9. Emergency Switch Test: Test the emergency switch to ensure it shuts off the furnace in case of a malfunction. This is a crucial safety measure.

10. Keep the Area Around the Furnace Clear: Maintain a clear area around the furnace. Remove any combustible materials or debris to prevent fire hazards and ensure proper ventilation.

Schedule professional furnace maintenance with HVAC Service Solutions and give your furnace some love and care it deserves.

How Oil Furnaces Impact the Environment?

Considering the environmental impact of oil furnaces is crucial in today’s climate-conscious era. While oil furnaces provide efficient heating, it’s essential to be mindful of their emissions. Advances in technology have led to cleaner combustion processes, reducing the environmental footprint. Additionally, exploring eco-friendly options within the oil or gas furnaces industry can align with the growing emphasis on sustainability.

Conclusion

Investing in an oil furnace ensures reliable heating for your home, especially in colder climates. With proper maintenance, you can enjoy the efficiency and warmth it provides. For professional and comprehensive furnace services, contact HVAC Service Solutions today. Ensure your oil furnace operates at its best, providing comfort and peace of mind throughout the seasons.

Frequent Asked Questions

How does an oil furnace differ from a gas furnace?

While both oil and gas furnaces serve as heating solutions, oil furnaces utilize heating oil for combustion, offering a high energy density and independence from the electrical grid.

Are oil furnaces energy-efficient?

Yes, modern oil furnaces are designed for efficiency, with advancements in technology optimizing fuel combustion and heat transfer, contributing to consistent and energy-conscious heating.

What are the main components of an oil furnace?

Key components include the burner, combustion chamber, heat exchanger, blower, and thermostat. Each plays a vital role in the ignition, heat generation, distribution, and regulation processes.

How does the efficiency of oil furnaces compare to other heating systems?

Oil furnaces offer competitive efficiency, particularly in colder climates. Their high energy density and durability make them a reliable option for consistent heating.

What environmental considerations should I be aware of with oil furnaces?

While oil furnaces have emissions, technological advancements have led to cleaner combustion processes. Exploring eco-friendly options within the oil furnace industry can further mitigate environmental impact.

What are the maintenance requirements for oil furnaces?

Regular maintenance, including cleaning and inspections, is crucial. This ensures optimal performance, extends the system’s lifespan, and addresses any potential issues promptly.

How often should I schedule maintenance for my oil furnace?

Regular maintenance, including annual inspections and cleanings, is recommended to ensure the optimal performance and longevity of your oil furnace.

Can oil furnaces operate during power outages?

Yes, oil furnaces can operate independently of the electrical grid, providing continuous heating even during power outages.

What safety measures should I take when operating an oil furnace?

Users should be well-versed in handling oil, conduct regular inspections for leaks, and address ventilation concerns. Following safety protocols ensures a secure and comfortable living environment.

Are oil furnaces dangerous for the environment?

Yes, the combustion of heating oil in oil furnaces produces emissions, but modern models are designed with cleaner combustion processes, reducing their environmental impact compared to older models.

Share