Table of Contents

The comfort of a warm and cozy home in the biting cold of a Canadian winter is often attributed to the efficient functioning of our heating systems. While many of us appreciate the warmth without delving into the intricate workings of our furnaces, there’s a small yet crucial component that plays a significant role in ensuring both safety and efficiency — the flame sensor. In our new article, we will examine the flame sensor, its location, and the pivotal role it plays in the seamless operation of your furnace.

What is a Furnace Flame Sensor?

Within the orchestration of furnace mechanics, the flame sensor assumes a pivotal role as an elemental safety apparatus. At its core, it functions as a discerning sentinel engineered to detect the presence of a flame within the combustion chamber of the furnace. Operating as a meticulous overseer, its principal objective is to validate the ignition of the burners. Upon receiving a signal from the thermostat to initiate heating, the furnace activates the burners, and the flame sensor ensures this ignition process by scrutinizing the existence of a flame. Should the burners fail to ignite for any reason, the flame sensor expeditiously interfaces with the furnace control board, instigating an immediate shutdown to preclude the potential release of unburned gas into the residence.

Role of the Flame Sensor

One of the primary roles of the flame sensor is to prevent the release of unburned gas into your living space. Imagine a scenario where the burners attempt to ignite but fail, leading to the continuous flow of gas. Without a flame sensor, this could result in a potentially dangerous buildup of gas, increasing the risk of a hazardous situation. The flame sensor acts as the last line of defense, immediately signaling the control board to shut down the system if it detects the absence of a flame, averting the possibility of a gas leak.

Safety is paramount when it comes to home heating systems. The flame sensor plays a pivotal role in maintaining a secure environment by ensuring that the burners are only active when required. Additionally, by promptly detecting and addressing issues with burner ignition, the flame sensor contributes to the overall efficiency of the furnace. An efficiently operating furnace not only keeps your home warm but also helps in conserving energy and reducing utility costs.

Where Is the Furnace Flame Sensor Located?

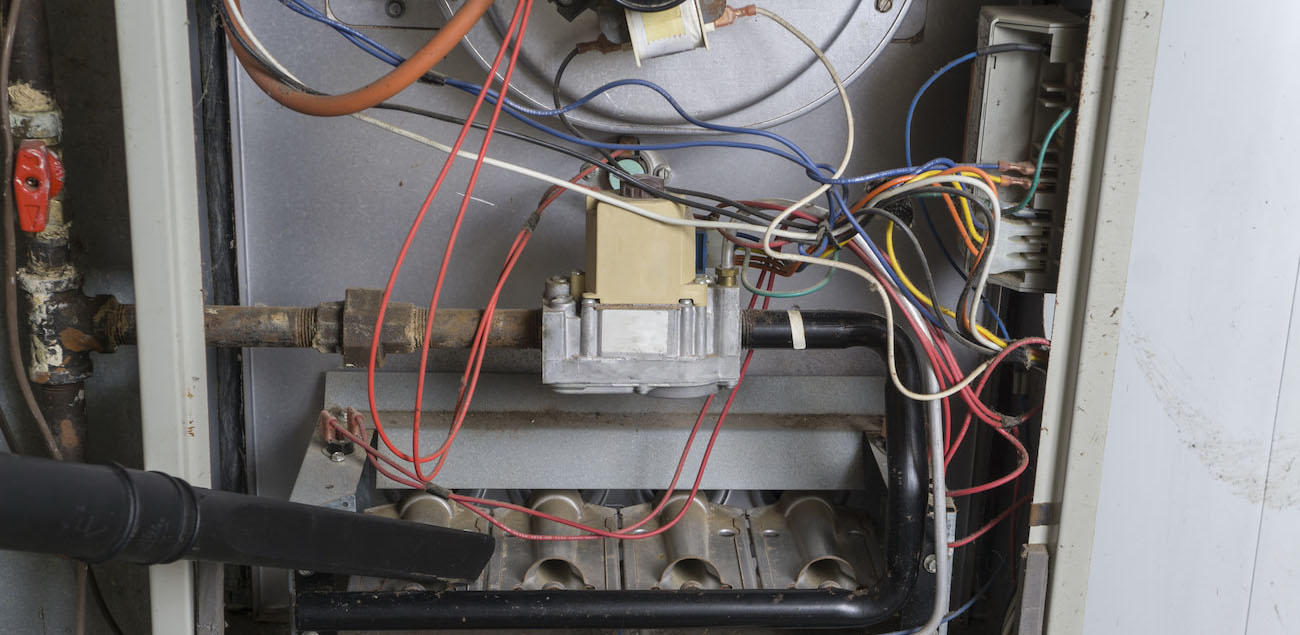

The flame sensor is typically situated within the combustion chamber of the furnace. This strategic placement allows it to have a direct line of sight to the burners. You can think of it as having a front-row seat to the combustion performance. While the exact location may vary depending on the furnace model and make, a common placement is near the burners, ensuring it can effectively monitor the presence of a flame.

Identifying the furnace flame sensor becomes especially critical during routine maintenance or troubleshooting. At HVAC Service Solutions, our seasoned professionals possess the knowledge to navigate the inner workings of various furnace models. If you find the task of locating the flame sensor too intricate, our team stands ready to assist, ensuring that your furnace functions optimally and that the flame sensor’s vital role is sustained.

How Does the Furnace Flame Sensor Work?

To ensure the safety and proper performance of your furnace, it’s crucial to unravel the inner workings of the flame sensor. Let’s explore how it functions.

- Ignition Sequence Initiation: The heating process kicks off with a signal from the thermostat, prompting the furnace to initiate the ignition sequence. The burners come to life in response to this demand for heat.

- Heat Exposure and Current Generation: As the burners ignite, the flame sensor, strategically positioned within the combustion chamber, is exposed to the ensuing heat. This exposure prompts the furnace flame sensor to generate a small electrical current.

- Confirmation of Burner Ignition: The generated electrical current serves as a confirmation signal to the furnace control board. It indicates that the burners have successfully ignited, and there is a flame present within the combustion chamber.

- Communication with the Control Board: The confirmation from the flame sensor is swiftly communicated to the furnace control board. This real-time interaction is crucial, as it informs the control board that the heating process can proceed.

- Fail-Safe Activation: In cases where the flame sensor does not detect a flame, it triggers a fail-safe mechanism. This communication prompts the control board to initiate an immediate shutdown of the system. This preventive action is essential to avoid the release of unburned gas into your home.

Check out the 10 most common furnace repair issues and step-by-step instructions on how to solve them in our previous guide.

The Most Common Issues with Flame Sensors and How to Troubleshoot Them

Despite their pivotal role, flame sensors can encounter issues that impede their effectiveness. Below, we explore some typical challenges associated with flame sensors and offer practical solutions.

Soot Buildup

Over time, soot may accumulate on the flame sensor, hindering its ability to detect the flame accurately.

Troubleshooting: Regularly inspect and clean the flame sensor. Gently remove accumulated soot using a fine abrasive pad or emery cloth. Ensure the sensor is free from any debris that might compromise its function.

Corrosion

Corrosion can develop on the flame sensor due to exposure to moisture or other contaminants.

Troubleshooting: Carefully clean the flame sensor using a soft cloth or a specialized sensor cleaning tool. If corrosion persists, consider replacing the sensor to maintain optimal performance.

Poor Electrical Connection

A loose or poor electrical connection can disrupt the communication between the flame sensor and the control board.

Troubleshooting: Ensure that the electrical connections are secure and free from corrosion. Tighten any loose connections and inspect the wiring for any signs of damage.

Incorrect Sensor Placement

If the flame sensor is misaligned or improperly positioned, it may not accurately detect the flame.

Troubleshooting: Refer to your furnace’s manual to ensure the flame sensor is correctly placed. Adjust the position if necessary, ensuring it has an unobstructed view of the burners.

Sensor Aging

Over time, the flame sensor may wear out, leading to reduced sensitivity.

Troubleshooting: If cleaning and maintenance do not resolve issues, consider replacing the flame sensor. Regularly check the manufacturer’s recommendations for the lifespan of the sensor.

For comprehensive solutions and professional assistance in addressing these challenges, contact HVAC Service Solutions. Our experienced team is well-equipped to diagnose and resolve issues with your furnace’s flame sensor, ensuring your heating system operates at peak efficiency.

Find more information about our furnace repair service in Canada via the link below.

How to Prevent the Flame Sensor Problems: Maintenance Tips

Preventing repair issues is often more efficient than addressing them after they’ve occurred, and when it comes to your furnace, regular maintenance emerges as the key to proactive care. Here are some expert advice to effectively care for their flame sensor:

Regular Inspection: Schedule routine inspections of the flame sensor to check for any signs of soot accumulation, corrosion, or misalignment. This proactive approach can help identify issues before they escalate.

Clean flame sensor: Periodically clean the flame sensor using a soft cloth or a specialized sensor cleaning tool. Gently remove any accumulated soot or debris, taking care not to damage the delicate sensor surface.

Avoid Harsh Cleaning Agents: When cleaning the flame sensor, refrain from using harsh chemicals or abrasive materials that could compromise its integrity. Opt for gentle cleaning methods to preserve the sensor’s effectiveness.

Check for Proper Placement: Verify that the flame sensor is correctly positioned, with an unobstructed view of the burners. Refer to your furnace’s manual for guidance on the appropriate placement.

Professional Maintenance: Consider scheduling professional furnace maintenance annually. HVAC professionals can conduct comprehensive inspections, address potential issues, and ensure optimal performance of the entire heating system.

Remember, a well-maintained flame sensor not only contributes to safety but also ensures that your furnace operates at its best, providing the warmth and comfort your home deserves. Regular cleaning and inspection are the investment in the longevity and efficiency of your furnace.

Conclusion

In conclusion, the flame sensor stands as a linchpin in the safety and efficiency of your furnace. Located within the combustion chamber, its vigilant role in confirming burner ignition and preventing potential hazards underscores its indispensability.

For expert assistance in maintaining a reliable furnace or addressing any issues, including those related to the flame sensor, don’t hesitate to reach out to HVAC Service Solutions. Our dedicated team is ready to ensure your heating system operates at its best, providing the warmth and security your home deserves.

Frequent Asked Questions

What is a Furnace Flame Sensor and Its Function?

The furnace flame sensor is a vital safety device in a gas furnace. Its primary function is to ensure that a flame is present when the furnace is operating. This small but crucial component is responsible for detecting the flame produced by the burners when the gas valve opens during the heating cycle. If the sensor detects a flame, it allows the furnace to continue operating. However, if it fails to detect a flame – possibly due to the burners not igniting – it signals the control board to shut off the gas supply. This action prevents unburned gas from accumulating in your home, averting potential hazards such as gas leaks or explosions. The sensor’s role is not only critical for safety but also aids in maintaining the efficiency of the furnace’s operation.

Where Is the Furnace Flame Sensor Typically Located?

The flame sensor is typically located inside the furnace’s combustion chamber, near the burners. Its strategic placement is essential for direct exposure to the flame, allowing it to effectively perform its monitoring role. While the sensor is generally positioned in a way that’s accessible for maintenance, its exact location can vary based on the specific furnace model and design. In many furnaces, you’ll find the flame sensor mounted on the burner assembly or close to it, often protruding into the path of the flame to ensure accurate detection. Homeowners looking to locate the flame sensor for maintenance or troubleshooting should consult their furnace’s manual, as it provides model-specific guidance.

How Does the Furnace Flame Sensor Work?

The operation of the flame sensor begins when the furnace’s heating cycle is initiated. As the burners ignite, the flame sensor, being in proximity to the burners, is exposed to the flame. This exposure enables the sensor to generate a small electrical current, a process known as flame rectification. This current serves as a signal to the furnace’s control board, indicating that the burners have successfully ignited and there is a steady flame present. If the sensor does not detect a flame – indicating that the burners have failed to ignite – it prompts the control board to shut down the furnace. This shutdown is a critical safety measure to prevent the accumulation of gas, thus safeguarding against potential gas leaks or explosions.

What Are Common Issues with Flame Sensors and How to Troubleshoot Them?

Common problems with flame sensors include soot or corrosion buildup, which can impede its ability to detect the flame. Signs of these issues might be the furnace cycling on and off frequently or failing to start. To troubleshoot, start by inspecting the sensor for any visible soot or corrosion. If present, gently clean the sensor with fine steel wool, sandpaper, or a dedicated flame sensor cleaner. Avoid using any harsh chemicals or abrasives. Check for any loose or corroded electrical connections, as these can also cause issues. Ensure the sensor is correctly aligned and securely in place. If cleaning and realigning the sensor do not resolve the issue, it may be time to replace it. When in doubt, especially regarding electrical connections or sensor replacement, it’s advisable to consult with a professional HVAC technician.

What Maintenance Tips Can Help Prevent Flame Sensor Problems?

Regular maintenance is key to preventing problems with the flame sensor. This includes periodic cleaning to remove any buildup of soot or debris, which is commonly done during annual furnace servicing. When cleaning, it’s important to use gentle methods and avoid harsh chemicals. Regular inspections are also vital to ensure the sensor is properly aligned and securely connected. Keeping the surrounding area clean and free of dust and debris can also help. Additionally, it’s important to have your furnace serviced regularly by a professional, as they can perform comprehensive maintenance, including a thorough inspection and cleaning of the flame sensor, and address any other potential issues. Remember, proactive maintenance not only extends the life of your furnace but also ensures it operates safely and efficiently.

How Often Should the Flame Sensor Be Cleaned or Maintained?

Regular maintenance of the flame sensor is crucial for the efficient operation of your furnace. It’s generally recommended to inspect and clean the flame sensor annually, typically as part of your routine furnace maintenance. This helps in removing any soot or corrosion that might have accumulated over time, ensuring the sensor accurately detects the presence of a flame. Regular maintenance also allows for the early detection and rectification of potential issues, such as misalignment or wear and tear.

Can a Faulty Flame Sensor Cause Furnace Malfunction?

Yes, a faulty flame sensor can lead to furnace malfunctions. If the sensor is dirty, corroded, or otherwise impaired, it may fail to detect the presence of a flame accurately. This can cause the furnace to shut down prematurely or not start at all, as the control system might interpret the lack of a signal from the sensor as an indication that the burners have not ignited, triggering a safety shutdown. Regular cleaning and maintenance of the flame sensor are essential to prevent such issues and ensure the furnace operates reliably.

Is It Possible to Replace a Furnace Flame Sensor on My Own?

While it is possible for a knowledgeable homeowner to replace a furnace flame sensor, it’s generally advisable to have it done by a professional. The process involves locating and accessing the sensor within the furnace, which can vary depending on the model and make. Additionally, proper handling and installation are crucial to ensure the sensor functions correctly. If you’re not familiar with furnace components and their maintenance, it’s best to contact a professional technician to avoid any potential damage or safety risks.

What Are the Signs of a Failing Flame Sensor?

Signs of a failing flame sensor include frequent furnace shutdowns, the furnace not starting, or the flame going out abruptly after ignition. These symptoms can indicate that the sensor is unable to detect the flame properly, either due to dirt buildup, corrosion, or a malfunction. In such cases, the sensor may need cleaning or possibly replacement. If you notice any of these signs, it’s important to address the issue promptly to ensure your furnace operates safely and efficiently.

How Do Environmental Factors Affect the Flame Sensor's Performance?

Environmental factors such as humidity, dust, and chemical vapors can impact the performance of a flame sensor. High humidity and dust levels can lead to quicker accumulation of soot or corrosion on the sensor, while chemical vapors from household cleaners or other sources can also cause deterioration. It’s important to keep the area around your furnace clean and well-ventilated, and to avoid using harsh chemicals that might damage the sensor or other furnace components.

Share